Stahl has opened its new Application Lab at Arzignano, in the province of Vicenza, home to the art of leather processing. This is not the first time the Dutch company, which specialises in the supply of leather for the automotive industry, interior design and fashion, has invested in Italy. Its first laboratory was opened in Tuscany, in Castelfranco di Sotto, and is dedicated to the manufacture of leather for shoes and bags.

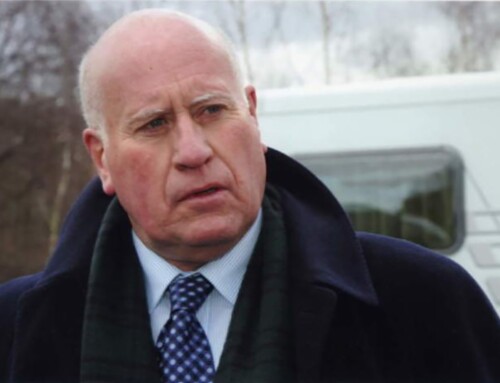

“We are happy to be able to invest here because we believe in the quality of the work in this country. Italy has always been a leader in design, fashion and taste. Stahl is a company that is constantly on the lookout for sustainability, so that we can work to the best of our ability to pollute as little as possible”, said Huub van Beijeren Chief Executive Officer and Board Member of Stahl. The new lab at Arzignano is equipped with cutting-edge machinery with which experts are able to create solutions that meet the needs of customers, in line with the diktats of sustainability and style.

At the inauguration of the plant we met Daniela Matyk, Automotive Leather Chemicals. We asked her what distinguishes the processing of material earmarked for leather goods and the leather that goes on car upholstery: “You find the main differences in the final stages of the working process. The leather for car interiors has to meet certain specifications. For example it has to be able to withstand 160 hours of UV ray exposure, be subjected to prolonged rubbing stress or resist the acidity of human perspiration, especially as regards gearshift and steering wheel upholstery. The stages in the leather working process are always the same regardless of the items involved: the lime pit for tanning then the dyeing phase and thereafter finishing”. With 2100 employees, 13 production sites and 38 laboratories in 24 countries, Stahl is one of the leading companies in the tanning chemicals sector with an expected revenue for 2017 of over 870 million euros.