“We had to convince the whole organisation that it would be possible to offer more variety with fewer platforms. The whole idea was about a fast and cost-effective development process, yet coming up with more creative design solutions”, Lobo explains.

From the outset, the idea was to use the Fiesta (Sub-B) platform to such an extent that not a single structural component had to be modified, thus keeping development costs as low as possible. This meant some tough talking with the engineering staff, who collaborated on the project with the same objectives as the design people. In the end, not only the platform as such but also the Fiesta dashboard, rocker panels and even the door aperture and the base of both A- and B-pillars were adapted to meet this goal. Also, the front-end structure including the crossbeam carrying the radiator and headlamps had to be included. Lobo did not consider this a restriction, nor does he feel he compromised.

“In modern design you can come up with a lot of unique creative solutions as long as you’re aware of the technical requirements before you begin a project. Only when you are confronted with the technical restrictions after you’ve started does it lead to frustration,” explains Lobo, who came up with some ingenious solutions to realise the Puma’s select and unique design. In order to push the screen position further forward, a steel spacer was incorporated between the left and right A-pillars, eliminating the need for a new structural bulkhead. The spacer functions simply as the lower base for the windscreen. Of the six pre-selected sketches, two were chosen for further development.

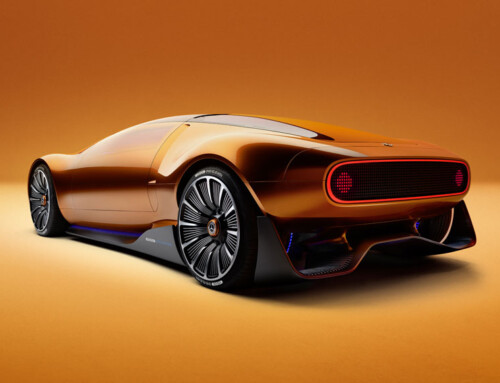

Known as the ‘blue’ and ‘red’ proposals, they differed in essential stylistic expression. The ‘blue’ had rather crisp and sharp lines, the ‘red’ featured more flowing lines, resulting in a softer and more rounded shape that enhanced the dynamic aspect. In particular those who remember the 1968 Ford Capri – and Lobo is one of them, since he even raced them – will recognise something of this nostalgic model’s side-window silhouette.

Both ‘red’ and ‘blue’ were developed in three-dimensional computer animation and offered for final selection to Ford management during the first week of 1994. And they chose the ‘red’ proposal, a decision supported by results from some small-scale market-research clinics in England, Italy, Germany and France. Only minor modifications were necessary to prepare a full-size model which could be presented to Ford chairman Alex Trotman at the end of March 1994. “So we really did a record job, creating a full-size model ready for product development within just 135 days,” is the proud comment of Claude Lobo, who adds that development by the engineering staff ran in parallel with the designers’ efforts.

One of the modifications concerned the headlamps. The design proposal suggested vertical lighting but as it had to be mounted on the existing under-bonnet beam (carried over from the Fiesta), some horizontal repositioning was required. But with the help of a unique Puma headlamp cover, the visual effect of the original design was not much affected. The longer front and rear overhangs of the Puma, in relationto those of the Ka, are exclusively the result of body-colour integrated bumpers. Another change from the original design was a more pronounced and integrated rear spoiler.

The article continues in Auto & Design no. 104