Porsche is revolutionising sporty seating: the company presents an innovative alternative to conventional bucket seat upholstery with the concept study “3D-printed bodyform full-bucket seat”. Here, the central section of the seat, in other words the seat and backrest cushions, is partly produced by a 3D-printer. Customers will be able to choose between three firmness levels (hard, medium, soft) for the comfort layer in the future. With this new technology, the sports car manufacturer is once again underlining its close ties to motor sports: the personalised sports seat follows the principles of driver-specific seat fitting customary in professional motor sports.

“The seat is the interface between the human and the vehicle, and is thus important for precise, sporty handling. That’s why personalised seat shells customised for the driver have been standard in race cars for a long time now,” says Michael Steiner, head of research and development at Porsche. “With the 3D seat, we’re once again giving series-production customers the opportunity to experience technology carried over from motor sports.” In addition to an ergonomic fit similar to that found in motor sports, this seat also delivers a unique design, lower weight, improved comfort and passive climate control.

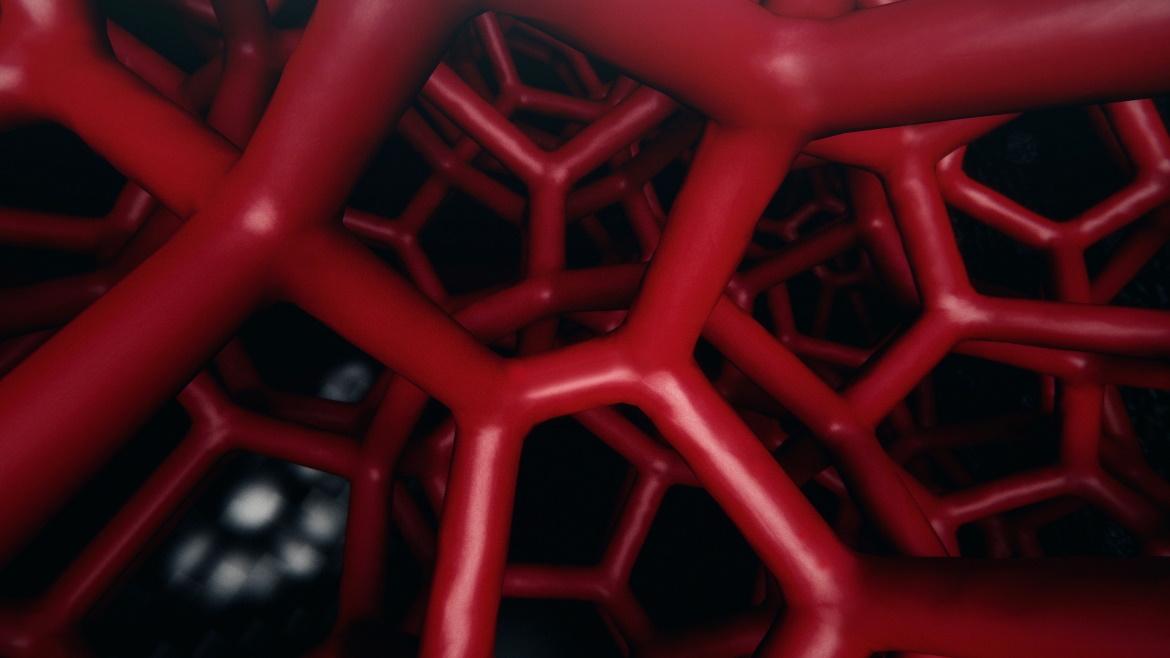

The seat is based on the lightweight full-bucket seat from Porsche and features a sandwich construction: a base support made from expanded polypropylene (EPP) is bonded to a breathable comfort layer consisting of a mixture of polyurethane-based materials made using additive manufacturing – in other words in a 3D-printer. The outer skin of the concept seat is made from “Racetex” and features a specific perforation pattern for climate control. Window panels provide a view of exposed coloured components in the 3D-printed lattice structure and give the full-bucket seat an unmistakable design. The seat will be available from Porsche Tequipment as a driver’s seat for the 911 and 718 ranges from as early as May 2020.