“What makes a car special is its ability to adapt to society’s needs even if radical changes have to be made to do so”. Hyundai and Genesis Global Design Centre’s Executive Vice President and Head SangYup Lee, stresses the crucial role played by design in the new Santa Fe. “Before launching a model, we do a thorough analysis of trends and try to predict what the future has in store”, Lee tells us speaking from Hyundai’s style centre in Namyang, South Korea. “The project got under way five years ago when the pandemic was still to come, but the trend of lengthy out-of-town car trips was emerging”, continues Simon Loasby, Hyundai design chief, connected from London. “A trend that exploded after Covid”, Lee says. “Here in Korea it’s called Chabak and has become highly popular”.

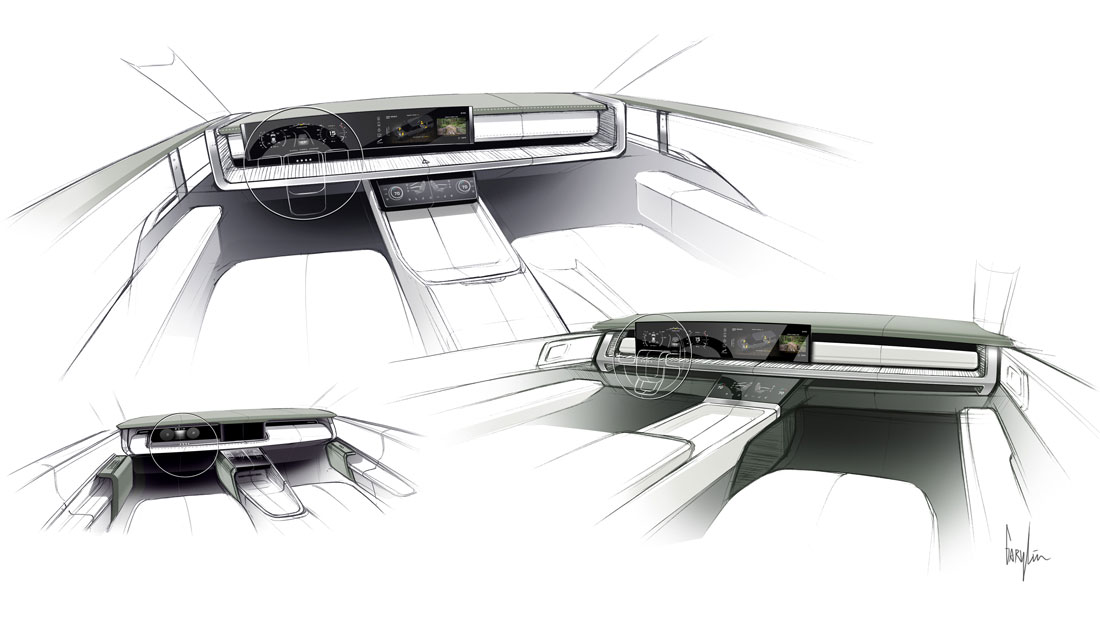

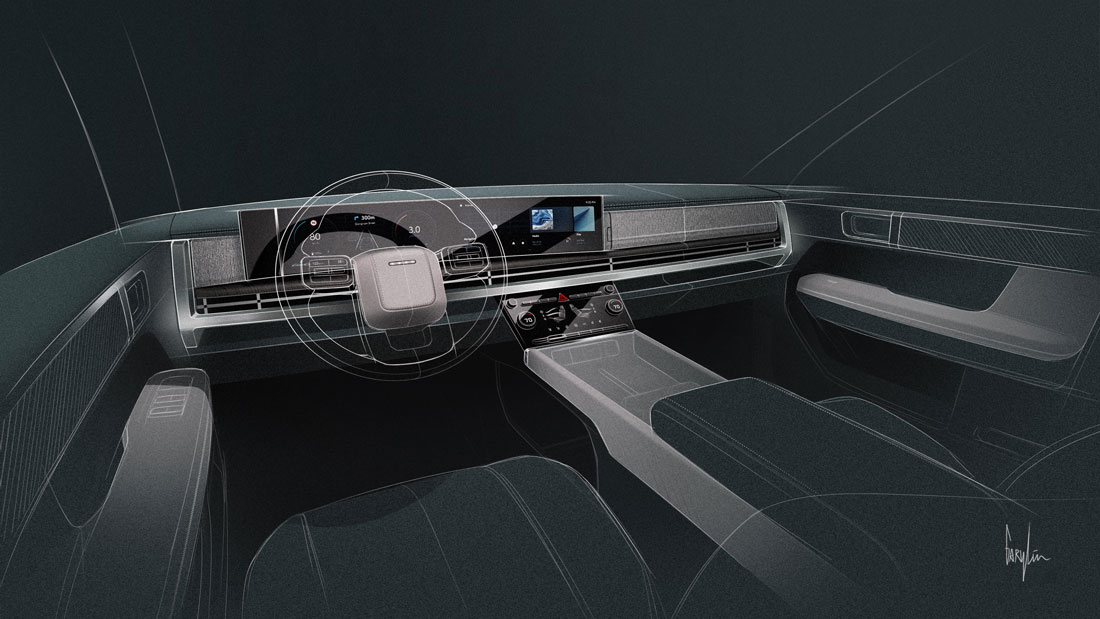

Built from the inside out

The new Santa Fe was thus built “inside-out” starting with the interior which is “roomy and practical, and so big you could sleep in it over the weekend sunk in nature”, Loasby continues. A concept that generated original and, when you are first confronted with them, disconcerting shapes: “I remember one of the key moments in the development stage: the moment we presented the wooden model to the top brass and the stunned looks on their faces. They couldn’t tell if it was a concept car or for real”, SangYup Lee laughs. “We joke about it now, but these were moments of considerable tension because we were determined to achieve this result”.

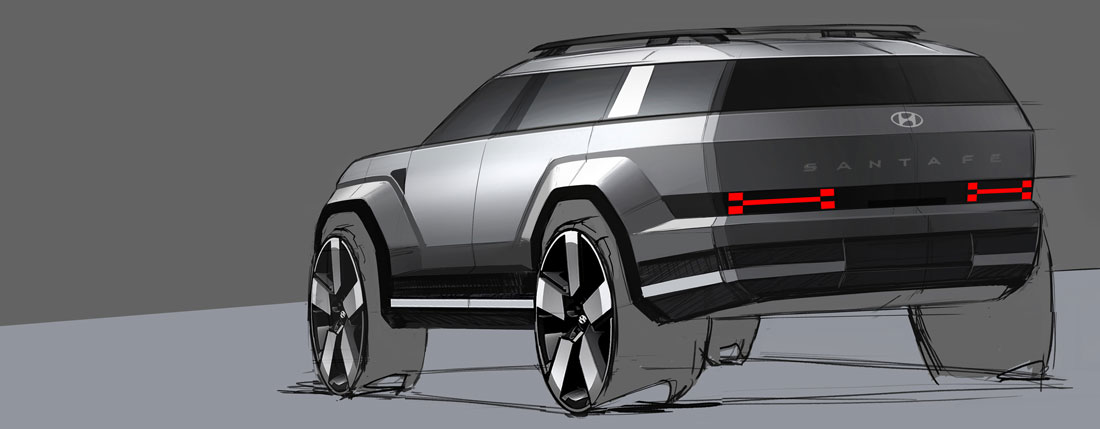

Square and mighty

The squared-off forms of the exterior are thus a natural consequence of maximising interior space. Surfaces are treated with a taste that Lee describes as “urban, not overly aggressive and ready for adventure, as cars like the Land Rover Defender or Ford Bronco can be. The Santa Fe has a powerful, boxy look, but it is geared to an urban lifestyle: we have created a new market segment. It is a car that meets the space needs of families, but it is also suitable for youngsters who can sleep in it if they want to when away for the weekend”.

Accessibility at the highest level

The stylistic core of the car is its “boxy design”, where squares and cubes are the shapes that define it and in whose creation the Hyundai design centres in Rüsselsheim (Germany) and Irvine (California) and the central design centre in Namyang played a part. While the front end is linear and the H-shaped headlamp graphics immediately catch the eye, the rear is even more striking. The trunk hatch is huge: “We wanted best-in-class cargo space and accessibility, and we achieved that by removing the taillights from the sides, placing them down inside a horizontal bar. That way there is no bulk and you can easily install all the accessories you need, from tents to equipment of all kinds”, explains Simon Loasby.

Working on aerodynamics

The Santa Fe’s boxy forms may seem a bit too chunky, but designers did a great job cutting down air resistance. “The Santa Fe has a Cx of 0.29, a significant improvement over the previous generation. Customer demands for this model mainly targeted space and functionality but not at the expense of efficiency”, Lee continued. Speaking of customer demands, Americans will be pleased to know that each seat has its own cup holder and the multiple interior compartments are decidedly practical thanks to what Loasby calls “smart solutions”. A couple of examples? The platform for disinfecting items with UV light and the big front armrest containing a deep storage compartment that can be accessed from both front and rear seats.

Furnishing materials

There is no shortage of technology, however: the centre tunnel houses two big chargers for smartphones, while in front of the driver are two 12.3-inch curved displays encased in a single glossy black frame. “You feel at home in the Santa Fe because in terms of materials, colours and styling you might be looking at modern interior design. We have raised the bar by looking at the premium world”, Lee explained, emphasising the importance of sustainability.

(Full article in A&D no. 263)