Volkswagen is using virtual concept cars for the development of production models. The next Golf generation is being developed with this new tool. Frank Ostermann heads the Virtual Engineering Lab in Wolfsburg, one of six competence centers now operated by Volkswagen Group IT. In the labs, IT experts, scientists and software specialists work together with research institutes and technology partners on the digital future of the company.

But why do we need virtual reality applications such as the virtual concept car? The virtual concept car saves development costs. The number of physical prototypes which need to be produced individually in a costly process can be reduced. This represents a considerable improvement in efficiency for the Volkswagen brand with its wide model range. The virtual concept car also saves time. As all the components are designed digitally, their data can easily be transferred to the program. The result is a virtual, properly functioning car of the next generation on which all the development team members can work together at the same time.

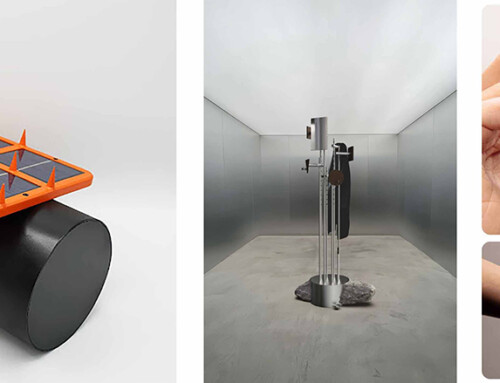

Ostermann and his team at the Virtual Engineering Lab are already working towards the next goal. To develop a virtual vehicle that allows a full experience and is fully operational, they have launched a research project at Stanford University in California. Users are to be able to feel the virtual concept car in the future. To make this possible, a system of fine, pressure-sensitive pins simulates all the shapes and contours of the interior. This will allow the user to feel the surfaces and controls which do not actually exist in the real world. “If we could actually feel a virtual vehicle, that would take us to an entirely new dimension”, said Ostermann.