For the past 113 years, in a location 60 km from Birmingham, they have hand built three cars a day using craftsmanship principles from an age that seem to have stood still. There are only 250 employees at Morgan, but the name of this legendary Malvern company is known all over the world and the creation of bespoke models gives it a come-and-see appeal for every designer. Perhaps that is why Jonathan Wells, Morgan’s head of design, has spent his entire career here, along with a group of eight passionate creatives who work in constant contact with the engineering and production departments. The stakes this time were pretty high: to breathe new life into the 3 Wheeler, Morgan’s iconic model that dates back to 1909.

First time with a car engine

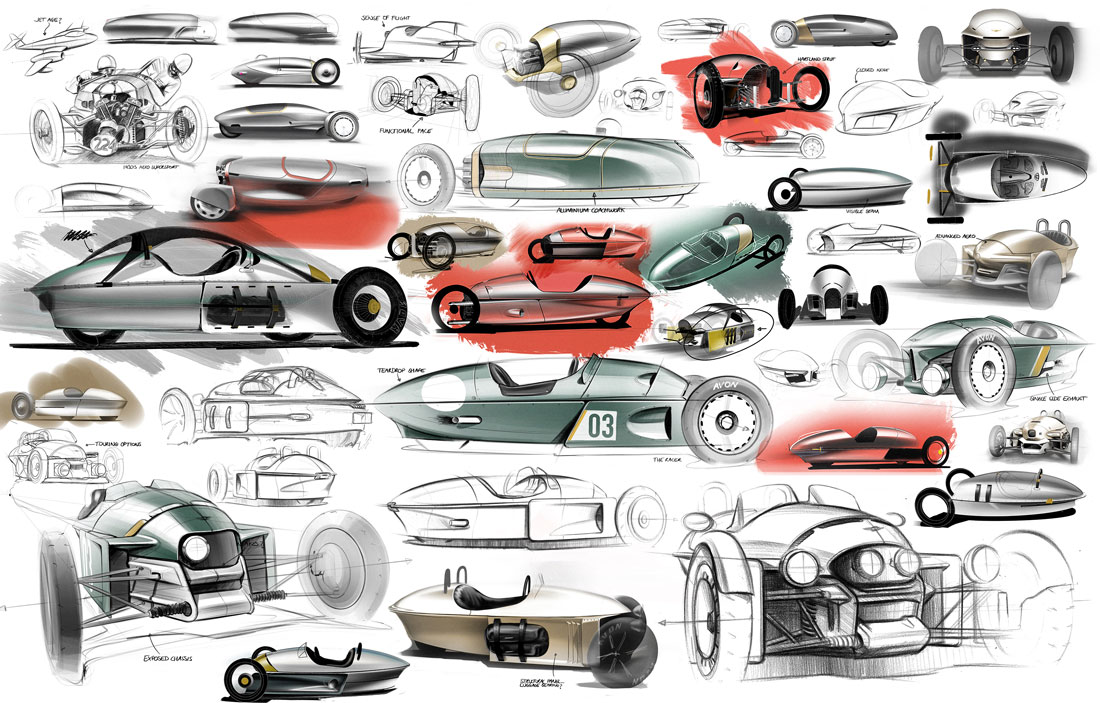

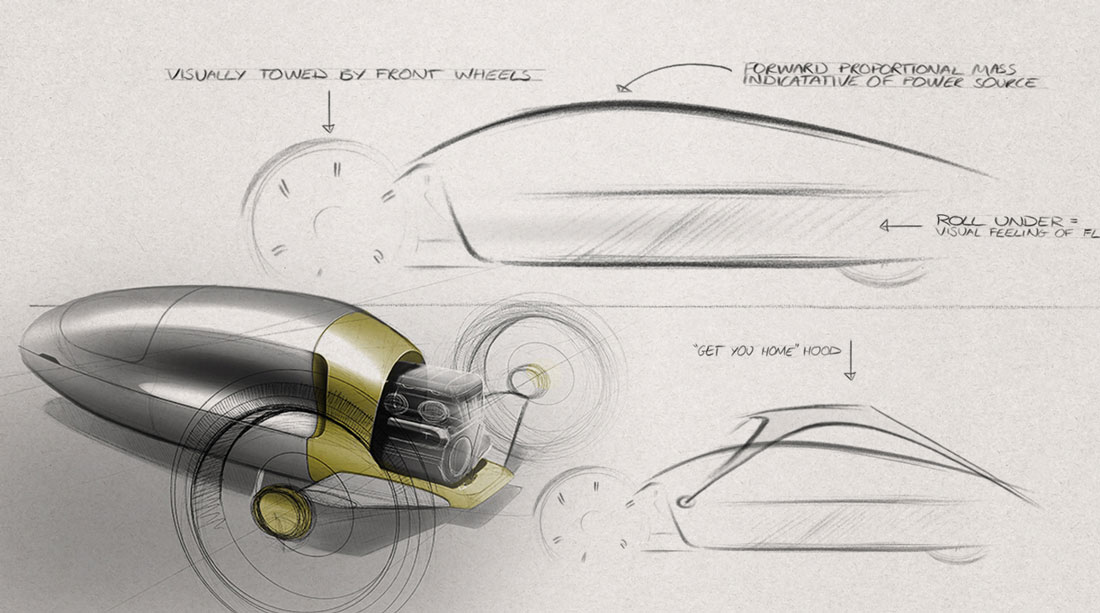

A vehicle halfway between a car and a motorbike, unique in its specifics: externally mounted engine and a single wheel at the rear. “It was a question of reviving a myth”, says Jonathan Wells, whom we meet in Malvern at the company headquarters that houses the style centre, production plant, administrative offices and a museum that tells the brand’s more than 100-year history. While the engines of all the historic 3-Wheelers were of motorbike origin and fitted at the front of the car, today’s Super 3 adopts a 1.5 Ford 118 hp three-cylinder: “Motorcycle engines are born with a high degree of aesthetics because of their visibility, as opposed to car engines, which are always covered by the bonnet”, continues Wells.

Timeless design

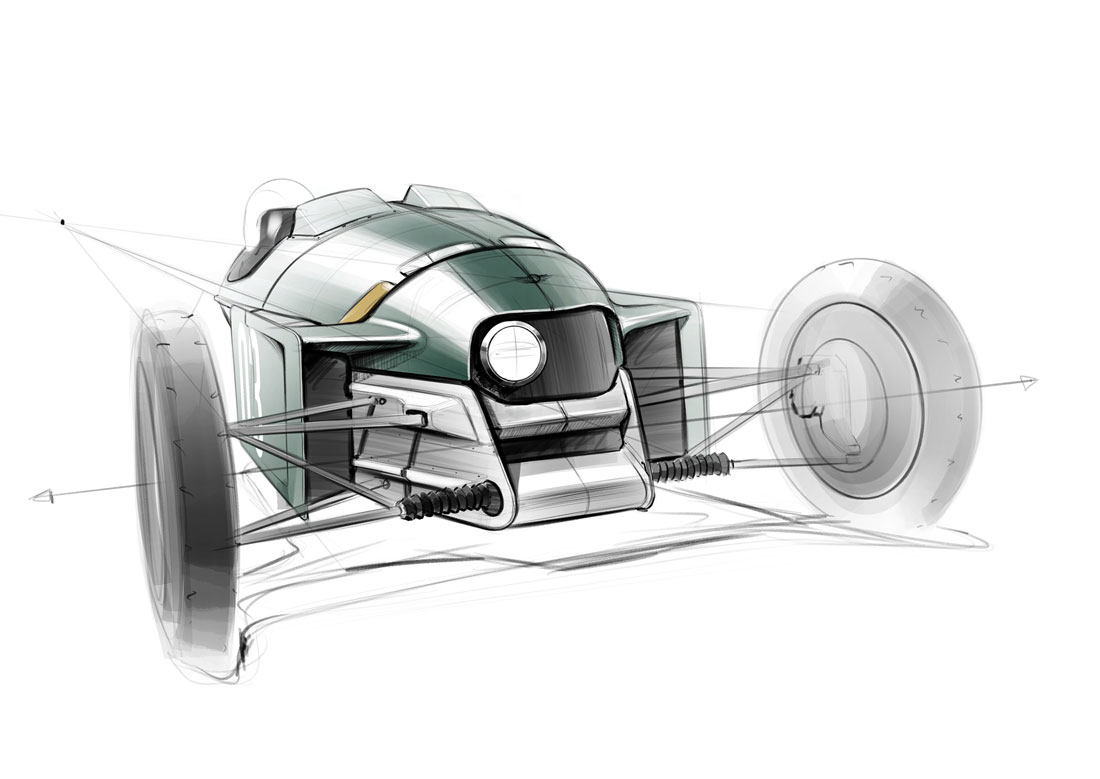

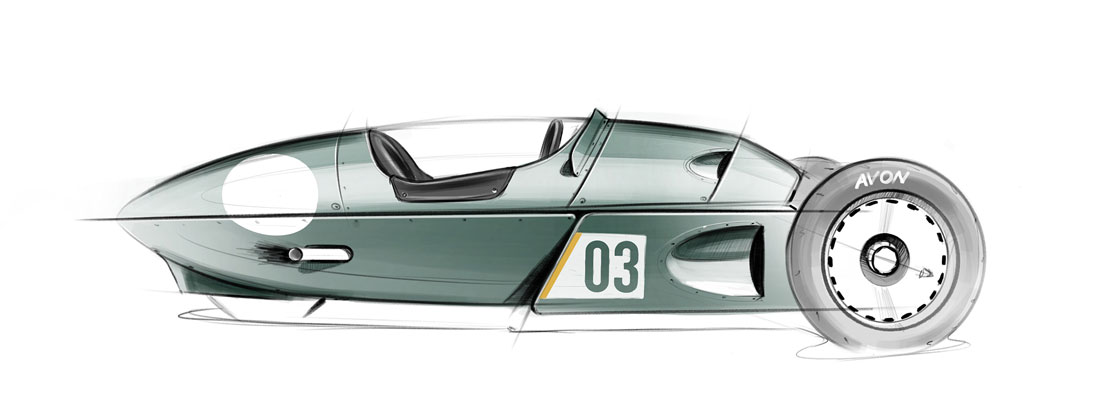

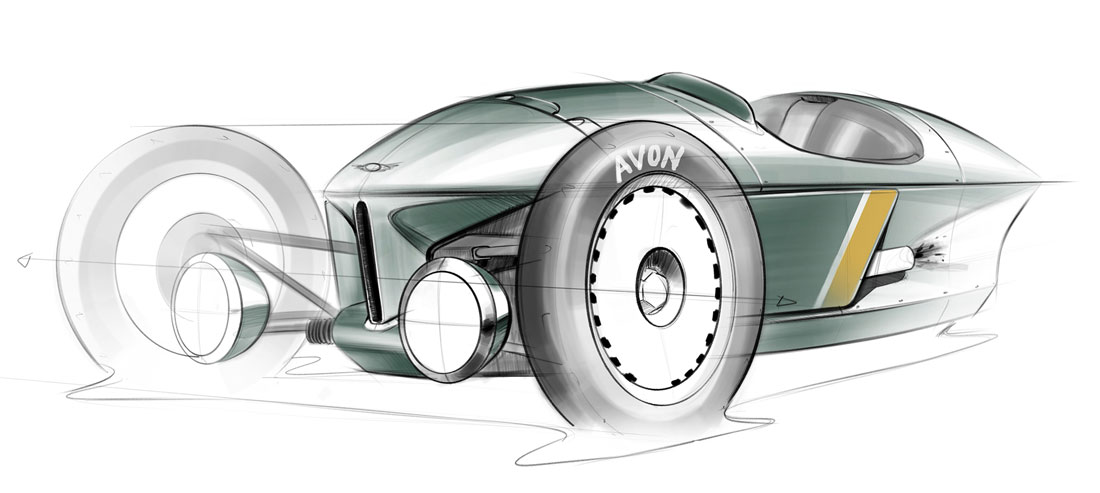

“So for the first time our new Super 3 has a covered engine, while the suspension arms and all the structural tubular parts of the car, which has an aluminium monocoque chassis, remain visible at the front”. This substantial modification has not, however, given the car a different look, and it appears both evolved and classic at the same time, thanks to immortal features like the two big round headlamps, and futuristic elements like the full wheels to improve aerodynamics. “We also designed the tyres, specially made for the Super 3 by Avon: there were no tyres on the market so thin and wide (20 inches) capable of withstanding high speeds.

Form is function

Every single opening in the bodywork has a specific aerodynamic or engine cooling function. “Form is function: there are no unnecessary ornamental elements, the founding principles are all about lightness”, Wells points out, as he shows us the elegant retro-style black mudguards that cover the front wheels: “The aesthetics are impactful, but without these the car would be undriveable because of the water splashing into the cabin”.

Maximum customisation

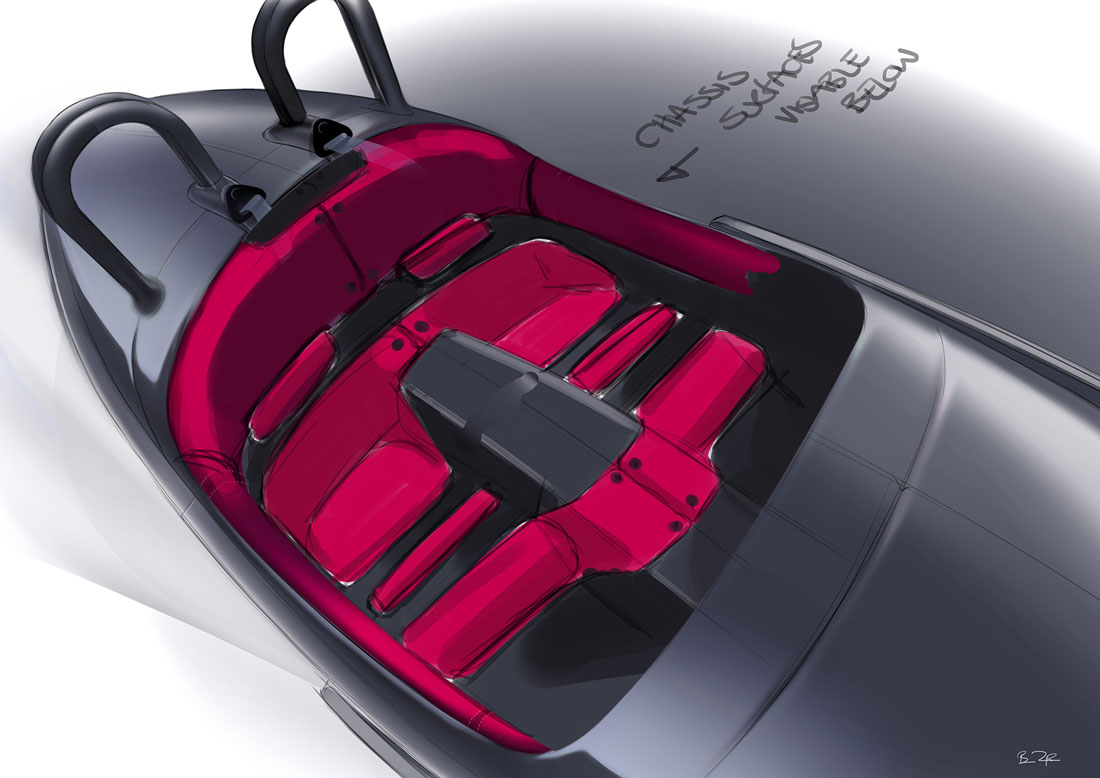

Speaking of the interior, the absence of windows and roof (only two small windshields are available, optionally in yellow) creates a strong connection between interior and exterior that is once again both stylistic and functional. “Customers can choose from over 400 combinations of colours and materials, but I love the tone-on-tone solution because it allows seamless communication between bodywork and interior”.

Waterproof interior

Every element of the interior is water-repellent, from the seat fabrics to the dashboard, there is a choice of four different steering wheels (the wood option is a given) and you can even have a small round map navigator installed behind the steering wheel. “One of the most fun things is to take customers through the whole process of making their Super 3, starting with the colours, choosing the materials and then following the production step by step. We set no limits: everything is possible here.”

(Full article in A&D no. 258)