Styling updates are frequent in the automotive world: the look is freshened up, certain finishes are changed, details are polished to keep up with the times. In agriculture, everything is different. Vehicles are only redesigned when there is a major technical innovation that justifies the change in look. This is what is happening with the New Holland CR11 combine harvester, which in addition to being the largest ever made, also sets new standards in terms of productivity and grain loss reduction.

Form follows function

The engineers at the Zedelgem plant in Belgium who designed it interacted with parent company CNH’s design centre in Turin led by David Wilkie to give shape to this revolutionary machine. “I am very satisfied with this project – said Wilkie – because, if on cars ‘design is king’, on work vehicles form always follows function. It is therefore more difficult to propose changes, which are always dictated by technical needs. On such an advanced and significant vehicle, everyone agreed right from the start on the need to show how much innovation there is on the CR11. It has been 20 years since the design language of New Holland combines last changed”.

A new design language

The chosen design has established itself not only because of its interesting aesthetics, but also because it is easy to replicate on so many different vehicles. In fact, it has borne a new design language for New Holland, which has been dubbed “Inspired by Nature” and which is also being replicated on other vehicles, the baler (presented even before the combine harvester, effectively anticipating its design criteria, although this was already defined) and the T7 Methane Power – LNG tractor.

Efficiency at the core

“The design language that defines the New Holland CR11 represents a new brand signature – said Giampiero Vietti, CNH Senior Designer, explains – which has been applied to the new tractors. There is a whole new generation of bonnets that follow the style born with the combine harvester”. Various sources of inspiration have dictated the design of this vehicle. “Although very large – added Vietti – with its shape, this CR11 wanted to emphasise the concepts of efficiency and the ability to fit into the environment. That’s why it has this yellow side, a colour that has always set apart New Holland combines, which is very sinuous and sculptural, while everything else is black. Even that sort of air intake that you can see in the middle of the body panel serves to streamline the shapes”.

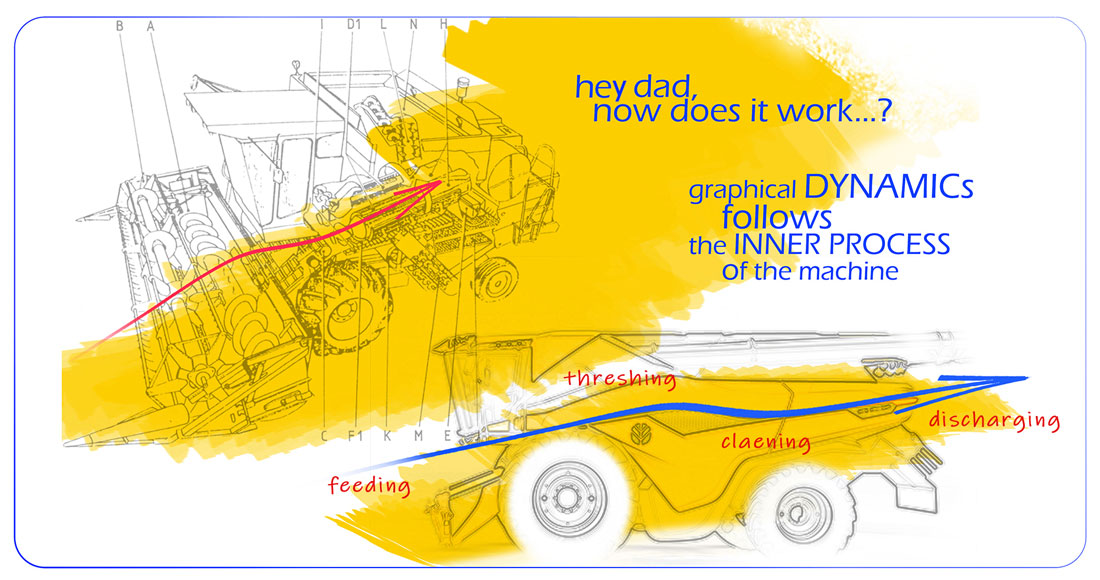

References to supercars

There is a strong inspiration from the world of cars, especially the curvy shapes of sports car bodies. These references to supercars make the vehicles decidedly more attractive. On the CR11, however, it was the functional component that drove the design, but the desire to give lightness to the vehicle was a fixed point. “Furthermore – added Vietti – with the new stylistic direction we have introduced the blue graphic decorative band: it is a visual element inspired by the machining process that takes place inside the machine, becoming a sort of signature that allows the New Holland brand to be recognised even from far away. For the sake of argument, one could identify the manufacturer’s brand even if it was not included in any logo. That is why that same decorative band has also been adopted on other products.

Color&Trim like a Ferrari

The automotive inspiration is also evident in the cabin. As always, it was function dictating style, but for the interior finishes, the aim was to reproduce the typical environment of super sports cars. The Colour&Trim solutions typical of Ferrari interiors were a strong inspiration, with precise and colourful finishes overlapping with a dark dominance of surfaces. “Our interiors have always been light – explained Wilkie – but for the CR11 we decided on a momentous change to black. With a dark interior and contrasting stitching, the perceived quality is higher”

(Full article in A&D no. 264)