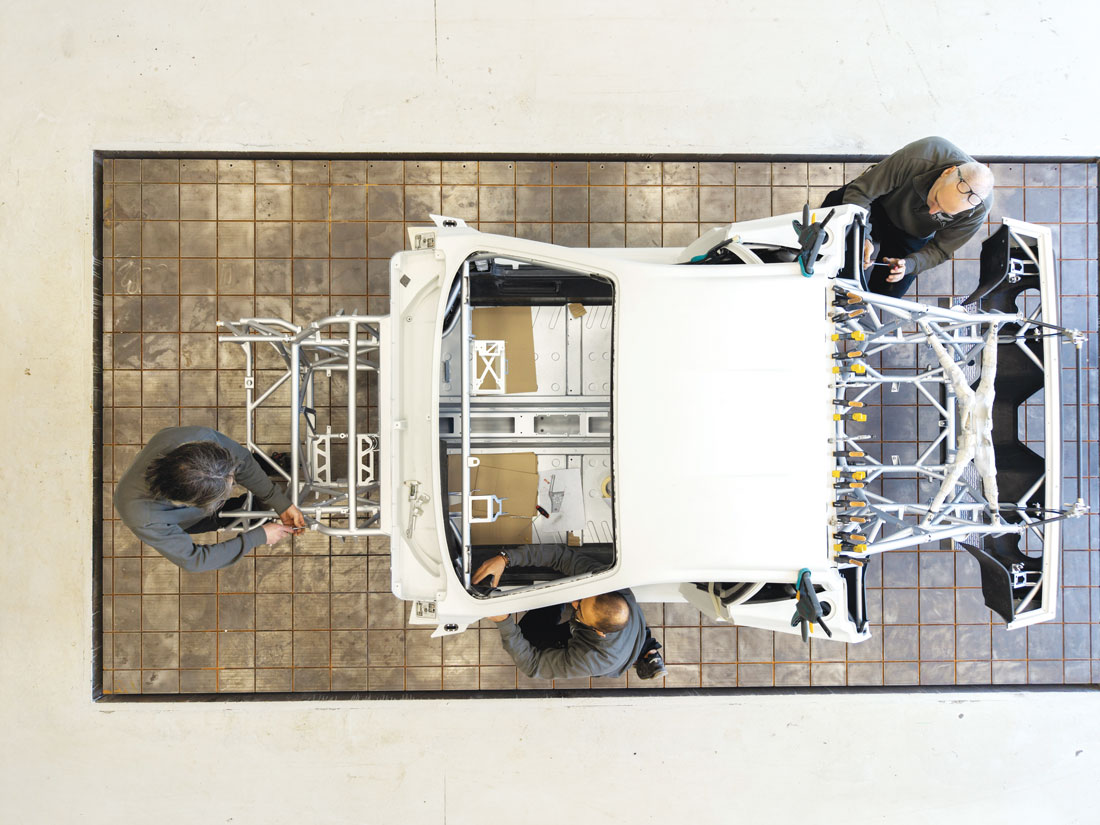

They say that numbers have no soul, but in transforming a digital project, which relies on sequences of numbers to trace volumes in virtual space, into a solid object requires craftsmanship care and sensitivity. And it is on this concept that the activity of GMA ProtoLab was built and developed, a company of the Falsone Group based in Orbassano, on the outskirts of Turin, an area where know-how and creativity are bound by an invisible yet extremely strong thread.

Founded in 2008, this atelier is led by CEO Giorgio Falsone, who learnt the secrets of perfect execution from his father Giovanni, applying them to the creation of models, show cars and special vehicles. “Our activity began in 2016 by adding pre-assembly and final assembly phases to the painting, rapidly expanding our expertise to the entire modelling process, including a careful study of the materials themselves.”

In brief, GMA ProtoLab gives shape and substance to projects that until a moment before existed, indeed, only on paper or in a digital file, creating concept cars and prototypes, but also pre-series models and taking part in the construction or completion of special vehicles in one-off examples or small series. As was the case, for example, for the sports cars from Kimera Automobili and with the painting of bespoke models and special editions from Maserati.

“Our main strength lies in our deep know-ledge of the manufacturing process and our ability to listen to and understand clients’ needs, but without encroaching on the realm of creativity.” No design. In fact GMA ProtoLab works exclusively and strictly on projects that are already defined, something that represents rather than a limitation a guarantee. Especially considering that the range of manufacturers with whom the company has relationships includes practically all the main European, Korean and Japanese makers, as well as several Chinese groups. One should also add those from sectors such as two-wheelers and heavy vehicles, right through to boats and helicopters.

“Style and mathematics arrive defined and approved,” emphasises Gioacchino Grande, Business Development Manager with ten years’ experience in the sector of independent design centres, “something fundamental for gaining the complete trust of manufacturers and design centres. In practice, data comes in to us and 100% finished models come out.”

The other distinctive element that Giorgio Falsone particularly values is that all expertise and capabilities are concentrated in a single entity, and the contribution of external partners is limited almost exclusively to raw materials: “GMA ProtoLab comes forward as a single touch point for each project. We can provide complete support at every stage, from feasibility study to production via engineering, with high industrial-level standards combined with our craftsmanship attention to detail.”

Full article in Auot&Design no. 274