Ostermann is a graduate engineer in computer engineering. At Volkswagen in Wolfsburg, he heads the Virtual Engineering Lab, one of six labs now operated by Volkswagen Group IT in Wolfsburg, Berlin, Munich and San Francisco. The latest lab is currently starting operations in Barcelona. At these labs, specialists from Volkswagen are working on the digital future together with research institutions and technology partnerships.

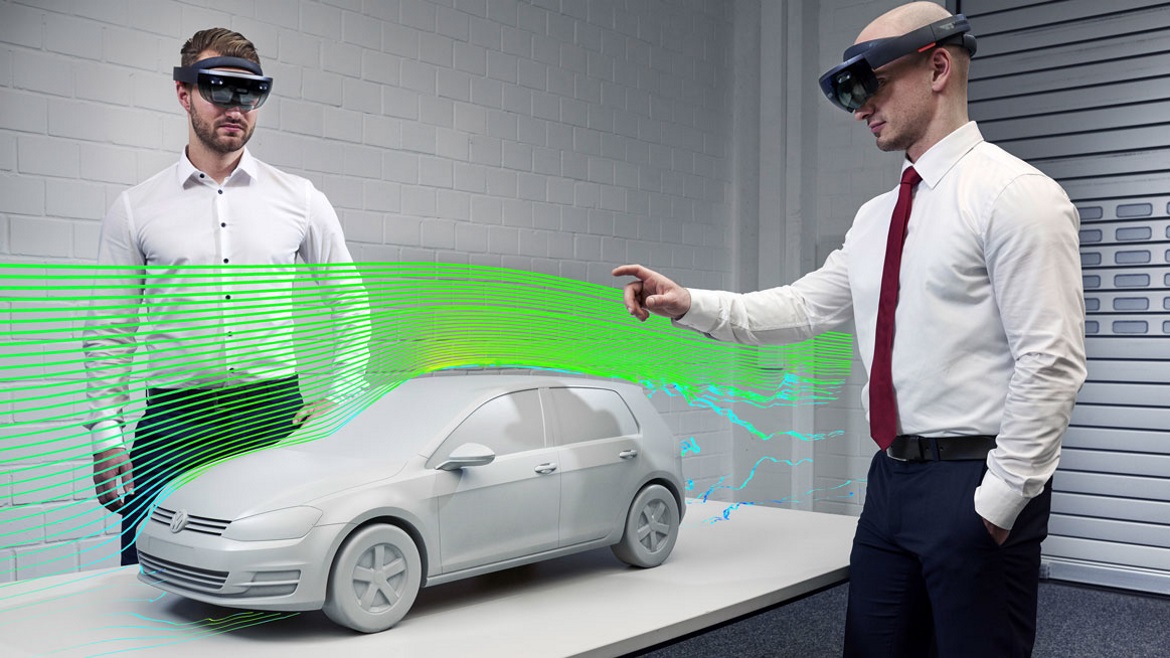

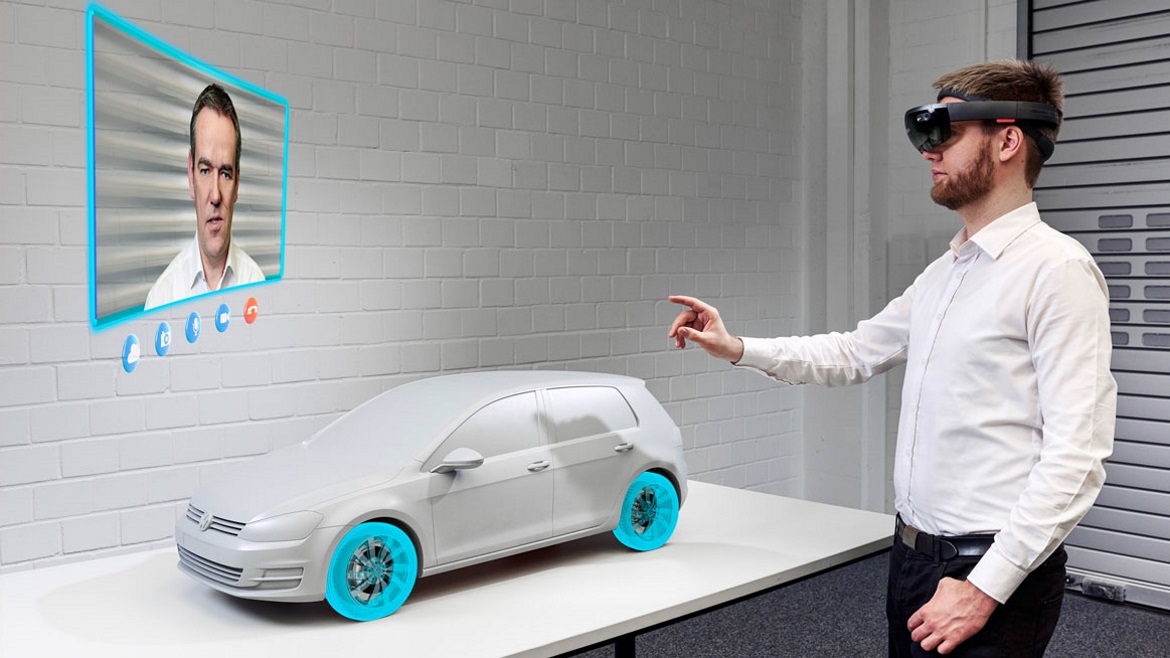

Ostermann is wearing “HoloLens” mixed-reality goggles. The mobile computer developed by Microsoft projects virtual content onto a physical object through gesture control and voice commands. Ostermann only needs to point his finger and the HoloLens projects a different paint color onto the Golf, installs different wheels and modifies the fenders.

«At Volkswagen, we have been using augmented reality and virtual reality for some time, mainly to obtain a three-dimensional view», says Ostermann. «We are now taking a major step forward at the Virtual Engineering Lab. We are transforming this technology into a tool for Technical Development. This will allow Volkswagen engineers to work on a virtual vehicle, to change its equipment as they wish and even to design new components virtually. They will be able to see the results of their work immediately. We are cooperating very closely with our colleagues from Technical Development and are already close to the first new vehicle concepts and design studies», Ostermann reports. What is the reason for this approach? Augmented and virtual reality help save time and development costs. Each step in the process can be made faster and more efficient.